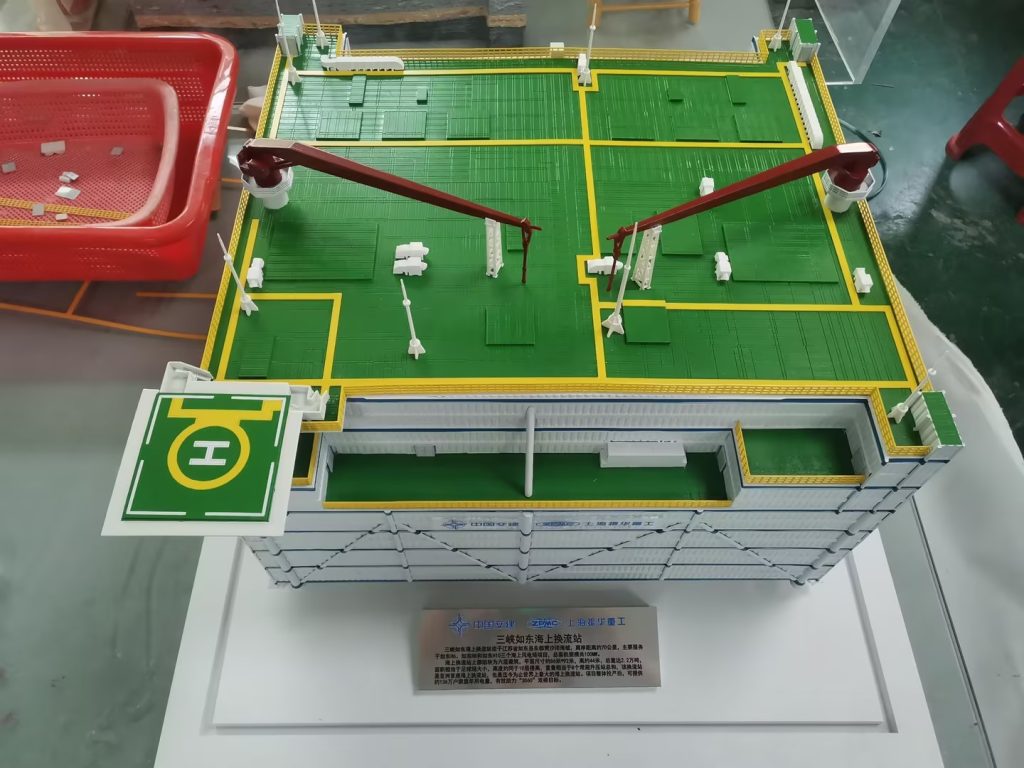

Model making scheme for offshore converter station

Professional Offshore Converter Station Model Manufacturing Solution

I. Core Material Selection

As professional model manufacturers, we carefully select the following materials to ensure model quality:

Main Structure: Aviation-grade ABS sheet (3mm) for platform base, engineering-grade PVC foam board for building modules

Detail Components: CNC metal parts for key equipment, photo-etched sheets for railings and fine structures

Special Materials: 3D printed resin parts for complex components, transparent acrylic rods for piping system simulation

II. Standardized Manufacturing Process

1. Platform Base Construction

Laser-cut ABS sheet with 45-degree edge chamfering

Embedded stainless steel reinforcement ribs for structural strength

Sprayed with industrial primer and anti-slip texture applied

2. Building Module Assembly

Layered construction: PVC sheet cut for box structure, acrylic sheet for observation windows

Equipment integration: Metal parts with brushed surface finish, embedded micro LEDs

Piping system: Acrylic rods heat-bent, reinforced with metal sleeves at joints

3. Professional Detail Finishing

Tinned copper wire for cable routing simulation, fixed according to real layout

Water transfer decal process for equipment nameplates and safety signs

Micro bearings enabling movable crane boom functionality

III. Industrial-Grade Painting Process

1. Base Coating

Entire model sprayed with gray primer, fully sanded

Building main structure coated with polyurethane topcoat using three-coat-three-bake process

Equipment areas finished with metal fluorocarbon electrostatic spray

2. Special Effects

Dry brushing technique highlighting metal edge wear

Was technique simulating oil stain deposition

Transparent resin + pigment creating seawater splash effect

This solution ensures 90% structural, detail and texture accuracy through professional materials, standardized processes and industrial-grade painting, meeting high-end customization requirements.