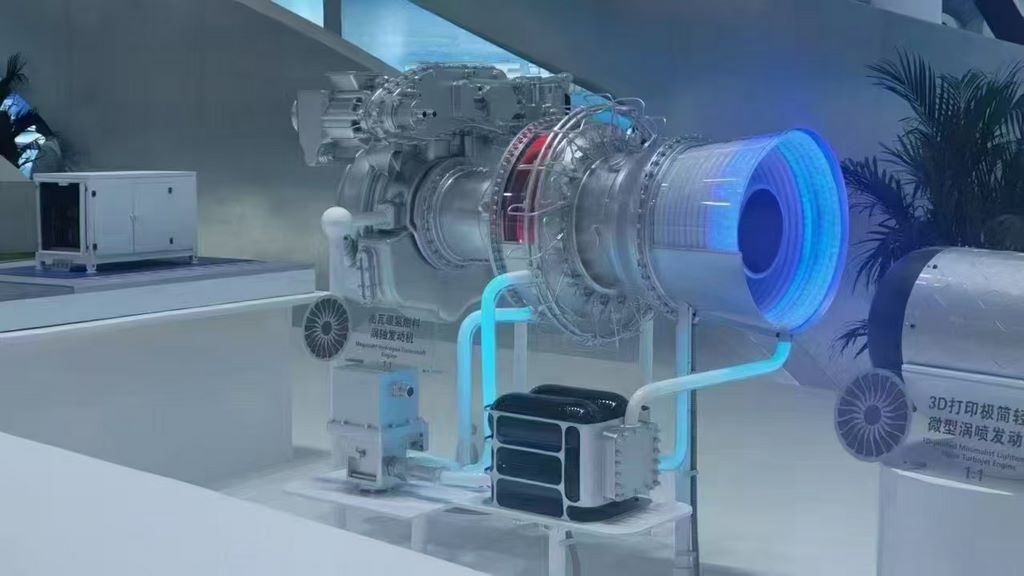

Manufacturer customized aircraft engine model

Customized production plan for aircraft engine models

1、 Material preparation stage

Main material selection

The skeleton is made of lightweight alloy material and formed through precision casting technology

The shell is made of composite resin material, which balances strength and detail expression

Special components use metal etching sheets and micro metal parts

Preparation of auxiliary materials

Professional model glue and filling agent

Fine polishing tool set

Metal polishing and oxidation treatment agents

2、 Core production process

Skeleton construction

Modular casting of engine main frame

Using mortise and tenon structure to connect various components

Internal embedded support structure enhances stability

Shell forming

Layered pouring of resin shell

Manually adjust surface curvature and thickness

Precise drilling installation of internal components

Detail production

Manual polishing and coating of turbine blades

The pipeline system uses miniature metal bends for shaping

The surface seam adopts metal wire inlay technology

3、 Surface treatment process

Basic Processing

Polish the entire surface to a smooth finish

Fill in seams and defects

Clean the surface and prepare for coloring

Multi layer coating

Uniform spraying of primer

Main color zoning, covering and spraying

Matte treatment of protective layer

Aging effect

Dry scanning method shows metal wear

Stain washing method simulates oil stain penetration

Pointillism to create a rusting effect

4、 Function implementation

dynamical system

Install micro motor driven rotating components

Set LED lights to simulate working status

Design movable cabin doors and maintenance panels

Display optimization

Customized acrylic display bracket

Design section display structure

Configure explanatory nameplates