Customization of Chemical Equipment Models

Case study on the production of teaching display models for chemical equipment

1、 Project positioning and production objectives

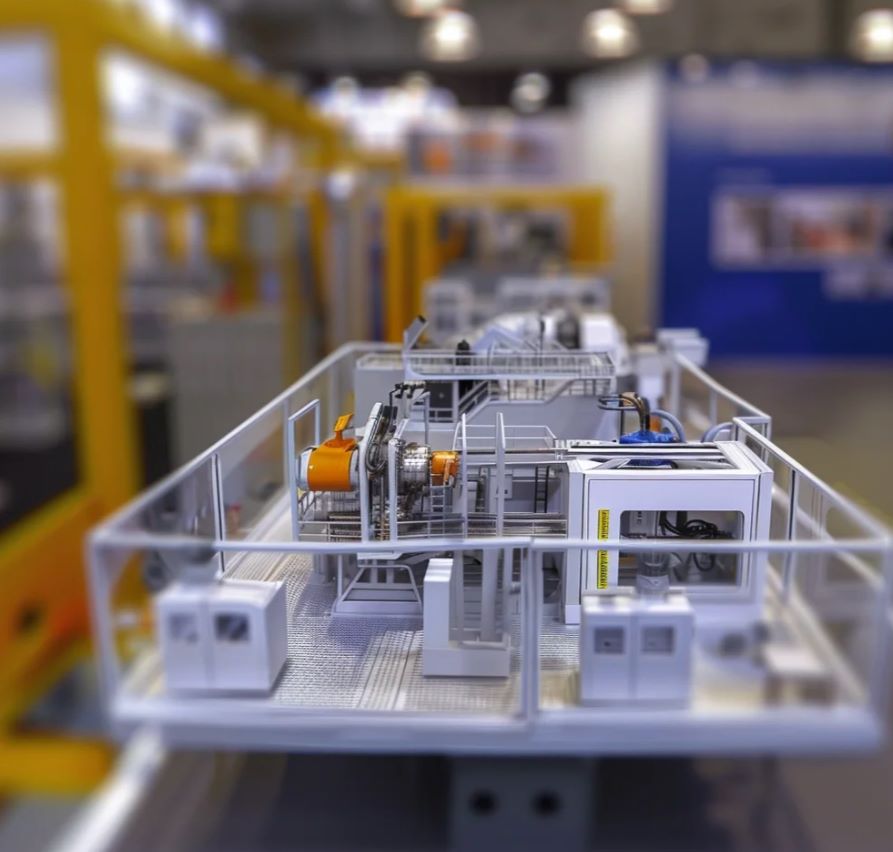

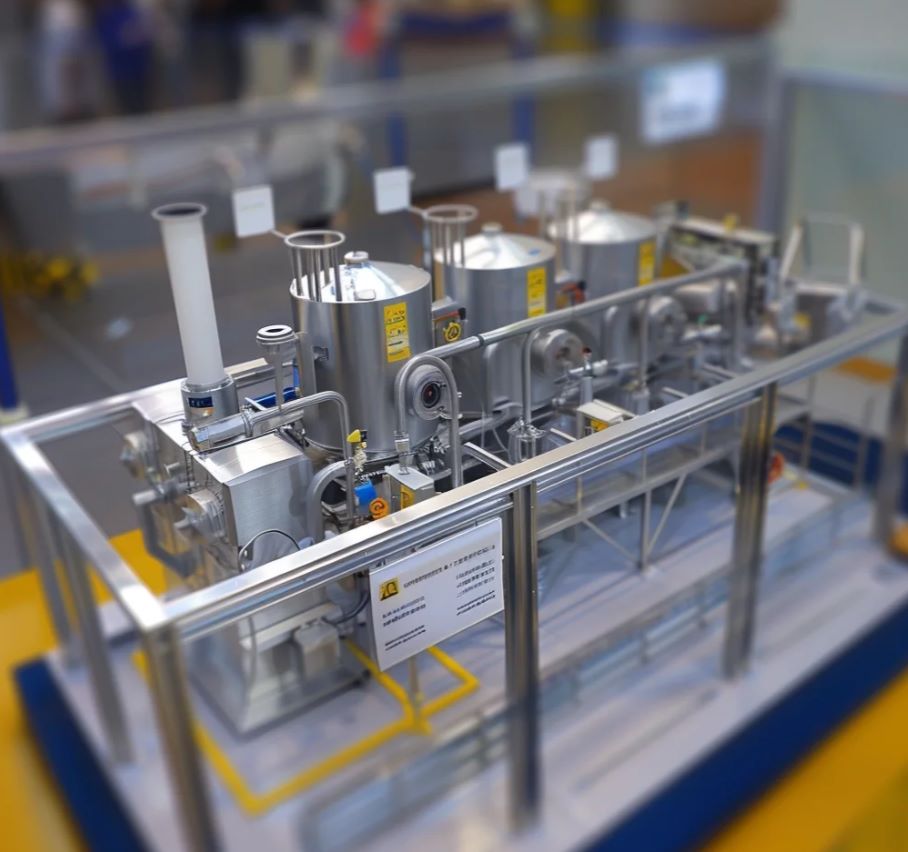

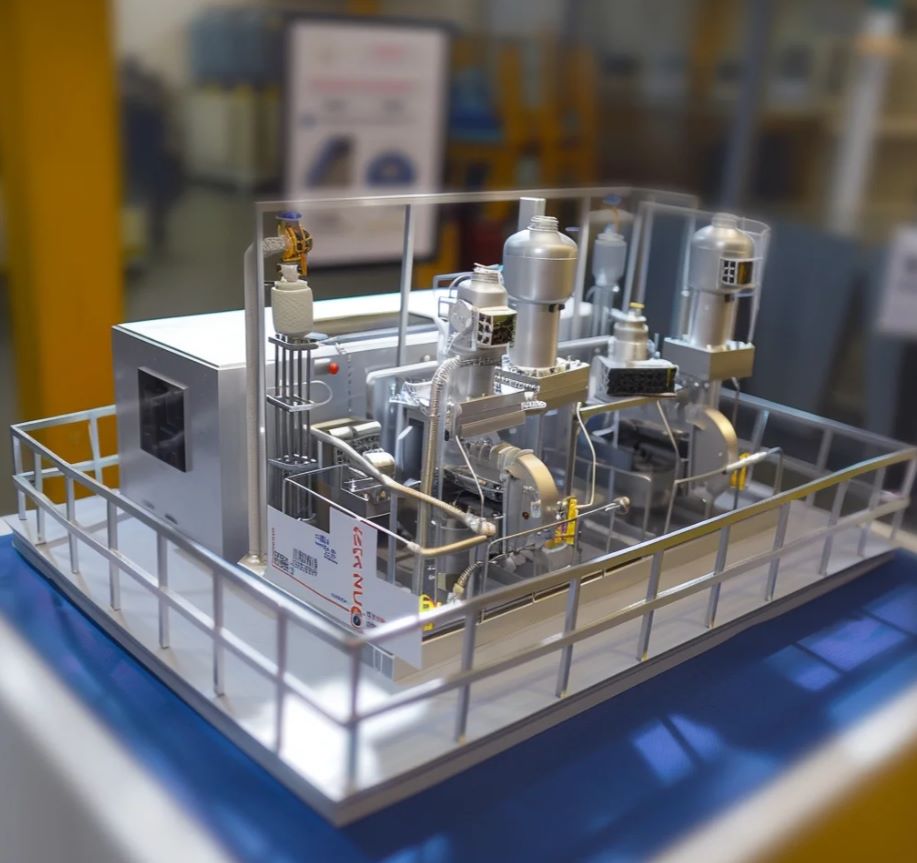

This production is a set of chemical process equipment models for teaching demonstrations, with a scale set at 1:20. The model fully presents the core components such as storage tanks, pipelines, pump valves, and control units in a multi-level processing system. The focus of production is to realistically reproduce the system logic and safety specifications of chemical equipment through scientific material representation and fine process processing, with an overall restoration rate requirement of over 90%, meeting the needs of teaching demonstrations and process demonstrations.

2、 Material selection and characteristic matching

The main equipment is made of high-strength ABS engineering plastic, which is molded through injection molding process to ensure smooth and natural surface of the tank body. The pipeline system uses differentiated material selection based on functional requirements: the main pipeline adopts PVC pipes with excellent flexibility, which are easy to shape various process directions; The sampling fittings are made of precision brass pipes to ensure the structural strength of small components; The connecting flange is formed by stainless steel turning, reproducing the real sealing structure. The guardrail platform uses a combination of aluminum alloy profiles to ensure strength and reduce overall weight.

3、 Production process flow

The model adopts a “modular unit” production scheme. Firstly, the storage tank system is divided into three independent units: the inlet tank, the treatment tank, and the collection tank. Each tank body is formed by spinning process, and the uniform thickness of the tank wall is controlled at 2mm. The pipeline system is pre fabricated with support frames, and the pipeline direction is shaped by hot bending process. All interfaces are designed with screw connections to ensure assembly accuracy.

The pump valve unit is made by flipping silicone molds, and key components such as impellers are individually carved and assembled. The control system uses transparent acrylic packaging, and the internal circuit board is made through etching process. During final assembly, positioning fixtures are used to ensure accurate alignment of each unit, and platform guardrails are installed in a plug-in manner for easy transportation and maintenance.

4、 Painting and Color Management

The painting scheme strictly follows the chemical industry standard color code. The main tank body adopts a bright yellow warning color and achieves uniform coverage through three thin sprays. The pipeline system is divided by function: the inlet pipeline is blue, the outlet pipeline is green, and the chemical addition pipeline is orange. All weld areas are highlighted with dark stain washing technology to emphasize contours, and equipment nameplates are made using water transfer printing technology to ensure clear and durable text.