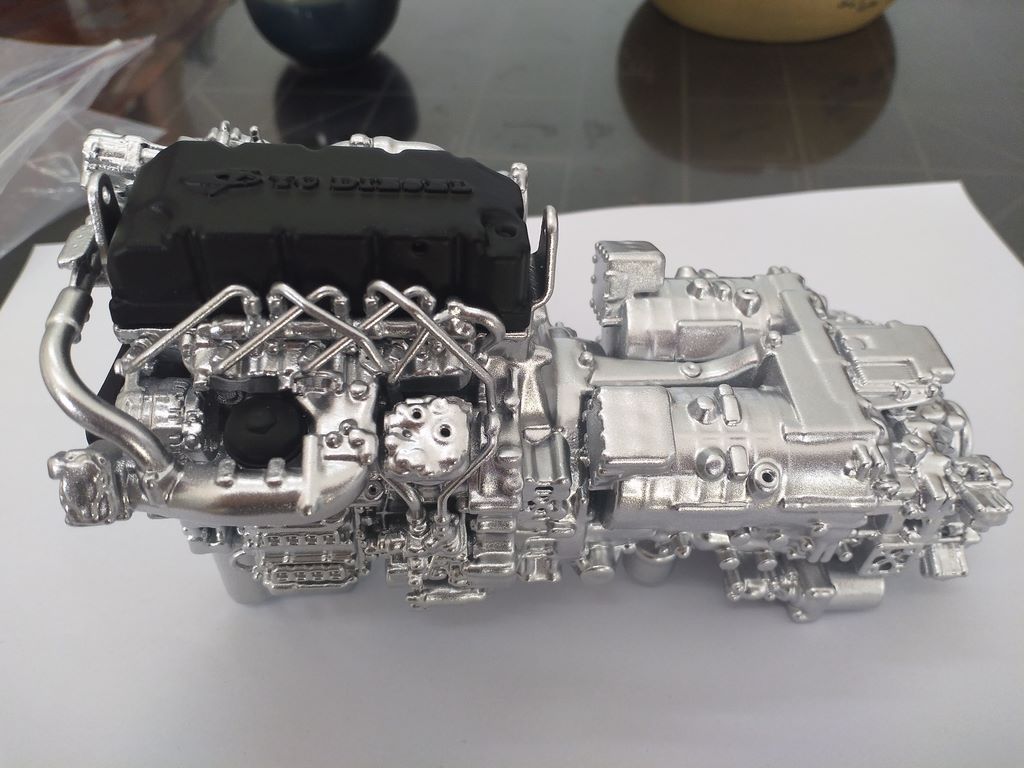

Engine equipment model manufacturer

Customized production plan for engine equipment model

1、 Material selection and structural design

Main framework

The engine body is constructed by combining a lightweight metal skeleton with a composite skin, and the structural stability is ensured through precision molding technology

The shell is made of a specially treated mixture of acrylic and resin, balancing strength and transparency

Core components

The cylinder group adopts a layered casting process, and the internal structure is accurately restored by etching metal sheets

The crankshaft connecting rod system is assembled with high-precision metal parts, and the surface is chrome plated to enhance the texture

The turbine blades are hand polished with special alloy materials, presenting a metallic luster

2、 Layered production process

Modular assembly

The model is divided into independent modules such as power system, transmission system, and control system, and fixed using buckle and adhesive technology. Each module is embedded with internal support structures, and the external joints are finely filled and polished.

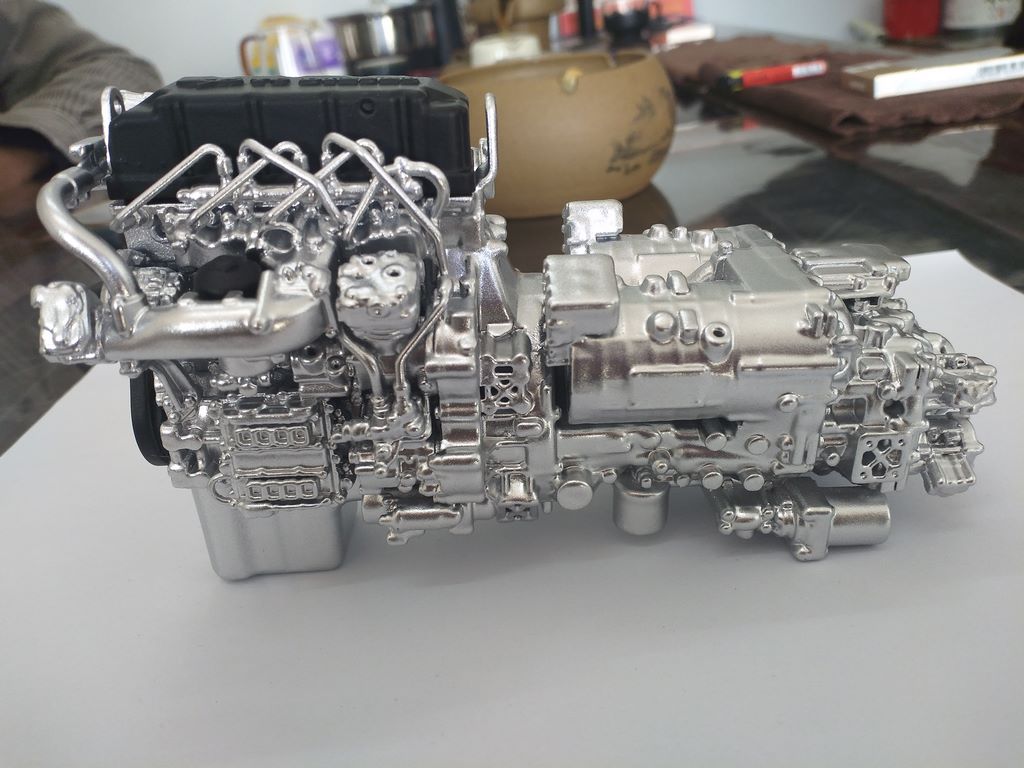

Detail presentation process

The surface seams are hand embedded with extremely fine metal wires, which are treated with special oxidation to form a natural texture

The oil system simulates the flow effect of lubricating oil through transparent resin and dye

The pipeline layout adopts miniature metal pipe benders for shaping, ensuring that the direction is consistent with the actual machine

3、 Coloring and aging system

Multi layer coating process

The basic color layer is uniformly sprayed with a spray gun to ensure a smooth surface

Special coating achieves color separation through fine covering, and the edges are manually transitioned

The protective layer is made of matte material, simulating the oxidation effect on the surface of a real engine

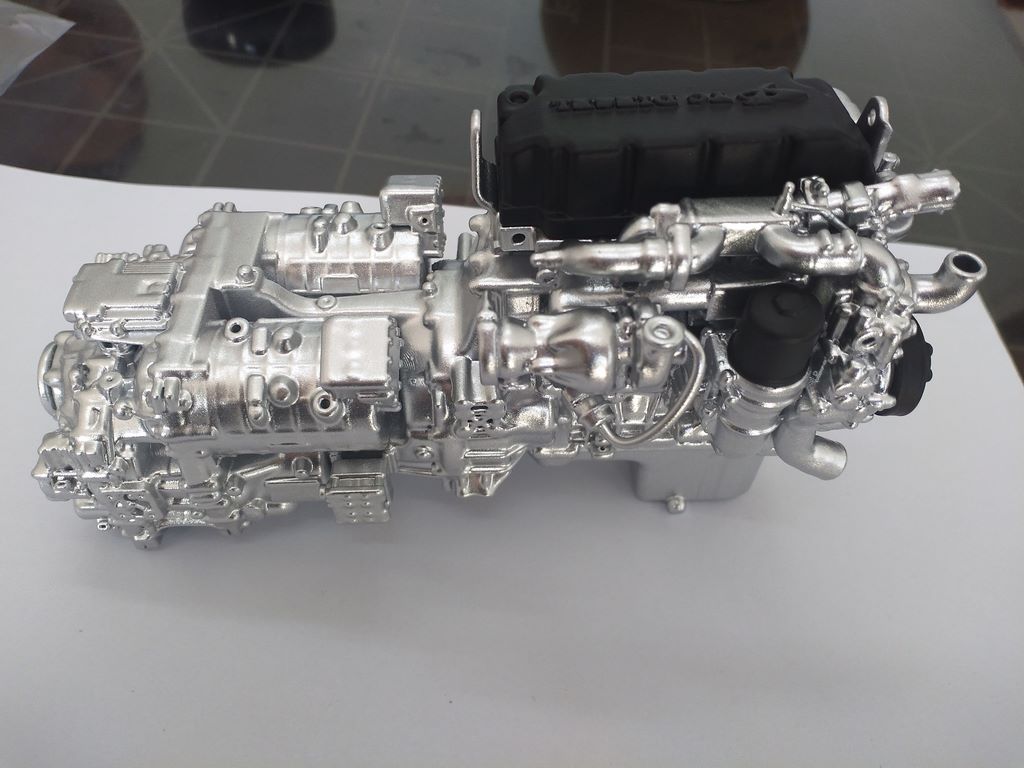

Dynamic effect processing

Gradient coating is used in high-temperature areas, with localized high-temperature discoloration treatment

The oil stain effect uses special techniques to simulate infiltration marks

Wear and tear areas show signs of use through dry cleaning process