Heavy duty machine tool miniature model customization manufacturer

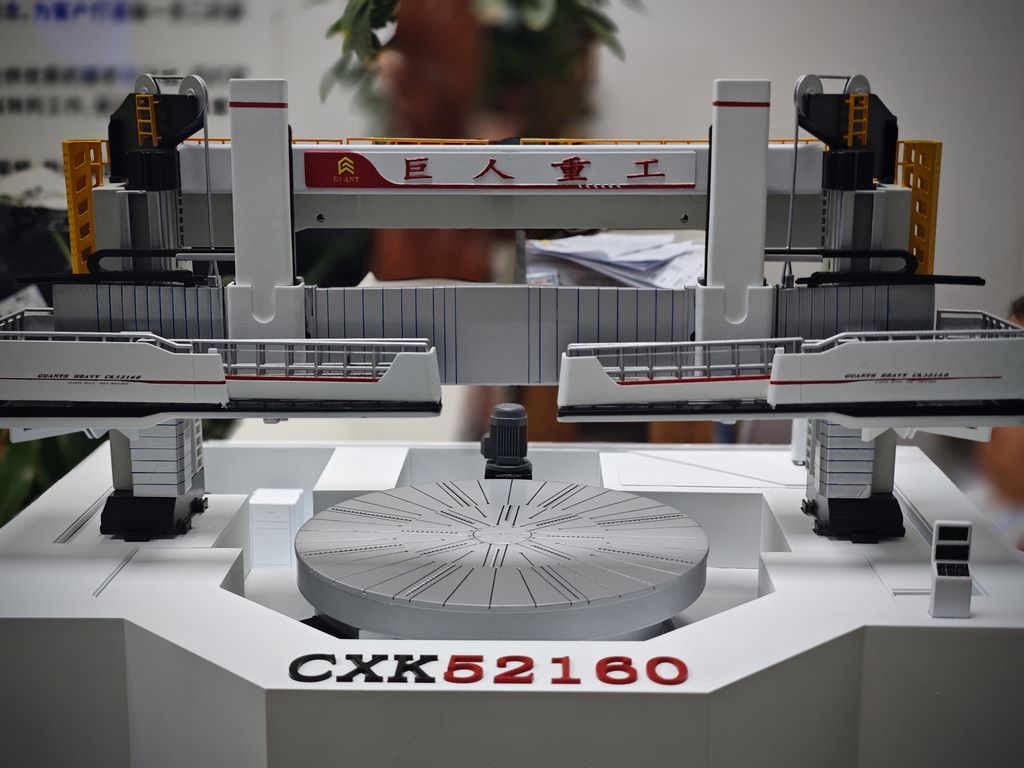

Case study on the production of display models for heavy-duty CNC machine tools

1、 Project positioning and production objectives

This production is a display model of the “Giant Heavy Industry CXK52160” CNC machine tool, specifically designed for enterprise product display and technical exchange. The model needs to accurately reproduce the main structure, functional zoning, and brand identity of the machine tool, with a focus on showcasing the technological sense and precision characteristics of modern heavy-duty machine tools. The production goal is to achieve over 90% appearance restoration through precise processing techniques, showcasing the industrial aesthetics of the machine tool.

2、 Material selection and characteristic matching

The main frame is made of 5mm aluminum plate CNC precision machined to ensure structural stability. Differentiated material selection for main functional components: The bed and columns are injection molded with high-strength engineering plastics to ensure accurate reproduction of details; The guide rail and workbench are precision machined with stainless steel, reproducing the metallic texture; The protective cover is formed by hot pressing 1.5mm thick ABS board to achieve smooth curved transition. The electrical system casing is made of transparent acrylic, and the internal structure is visible.

3、 Production process flow

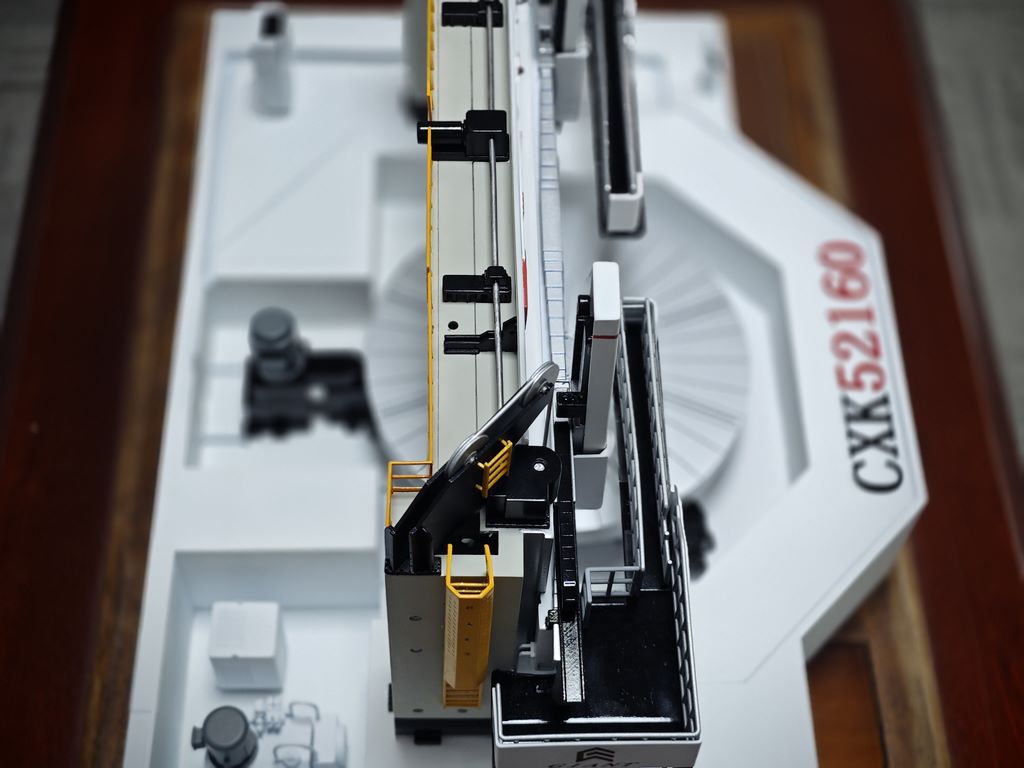

Adopting the “modular layered production” scheme. Firstly, the core components such as the bed, columns, and crossbeams are separately manufactured and injection molded using precision molds. The guide rail system is manually refined to ensure precise fit, with all moving parts retaining appropriate clearances. The protective cover is made through vacuum forming technology, and the inner lining is reinforced with ribs to ensure shape stability.

The production of detailed components is particularly crucial: the yellow safety barrier is made using precision etching technology to accurately reproduce the standard structure; The pipeline system is arranged according to functional zoning, and the direction conforms to the engineering logic; The brand logo uses high-definition water sticker technology to ensure clear and recognizable text. Special positioning fixtures are used during final assembly to ensure the installation accuracy of each component.

4、 Painting and surface treatment

The painting scheme strictly follows the enterprise standard color scheme. The main structure uses mechanical white as the base color and achieves uniform coating through three thin sprays. The functional components are distinguished in standard yellow to create visual contrast. The guide surface retains the original metal color and is only treated with transparent protection.

Surface treatment pays attention to details: fine washing treatment is carried out on the combined parts to enhance the three-dimensional sense of the structure; Frequently using dry scanning techniques to depict usage traces in the operating area; The brand logo is accurately positioned through water transfer printing technology, with clear edges. Finally, apply semi gloss protective paint as a whole to achieve a uniform glossiness.

5、 Quality control and display effect

The finished product undergoes strict testing: dimensional accuracy verification ensures that each component meets the proportional requirements; Structural stability testing ensures long-term display without deformation; Visual effect debugging and optimization of viewing experience. The final model accurately reproduces the modernity of heavy-duty machine tools and showcases the technological beauty of industrial equipment through exquisite craftsmanship, becoming an important carrier for enterprise display.

6、 Featured craftsmanship details

The moving parts adopt a real guide rail structure, which can simulate the operating state

The workbench is carved to express texture details

Safety signs use fluorescent colors to improve recognition

Pipeline systems are arranged by functional color separation

Base counterweight treatment enhances stability