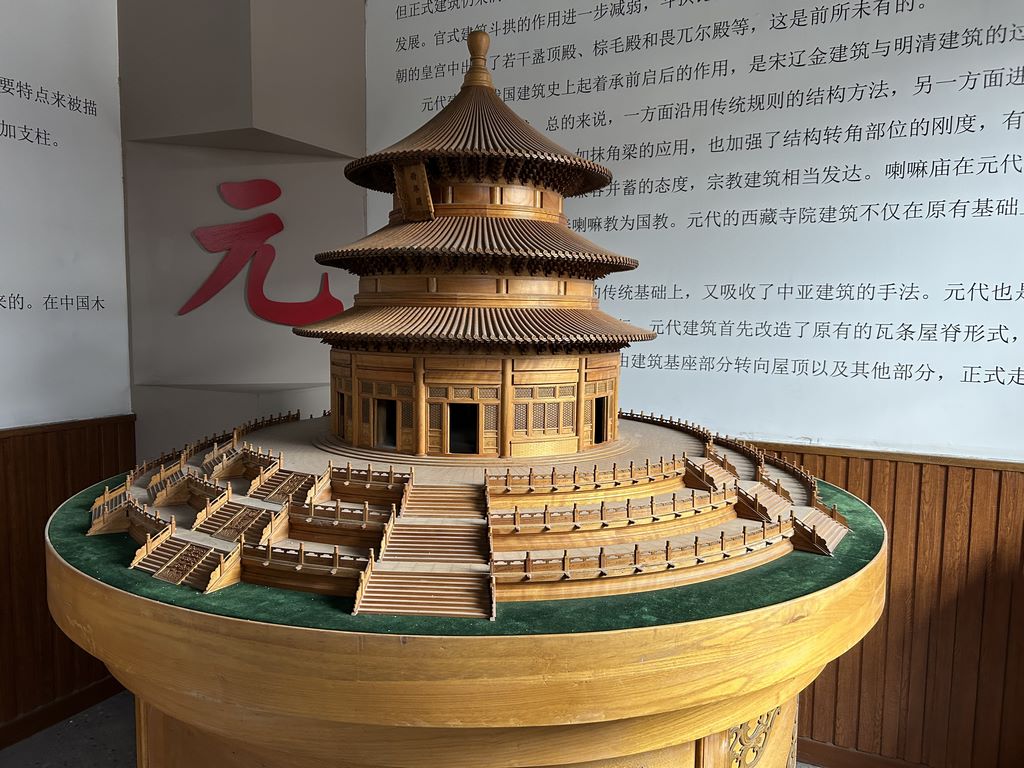

Micro model production of the Hall of Prayer for Good Harvests at the Temple of Heaven

Miniature model production plan for the Hall of Prayer for Good Harvests at the Temple of Heaven

1、 Design research and preliminary preparation

The primary task in creating classic ancient architectural models such as the Hall of Prayer for Good Harvests is to conduct in-depth research on its historical background and architectural form. The Hall of Praying for Good Harvest is a round building with triple eaves and spires. It needs to focus on its unique round plane, domed roof, blue glazed tiles and exquisite color paintings. By consulting surveying drawings and historical photos, the entire structure is disassembled into core modules such as platform foundation, column grid, triple eaves, and roof, and precise 1:50 scale drawings are drawn to ensure coordinated proportions of each component.

2、 Material selection and matching

The main structure is made of finely textured hardwood such as oak or nanmu, which ensures structural strength and is easy to carve. The roof tiles are handcrafted using finished resin tiles or clay to recreate the three-dimensional texture of glazed tiles. Decorative components such as arch of wooden architecture and rafters use laser carved basswood laminates to ensure accuracy. Prepare model specific water-based paint and metallic pigments for the color painting section, and finally use matte protective paint to unify the overall texture. The base of the booth is covered with green velvet cloth to simulate grass, and the fence is handmade with fine wooden strips.

3、 Core production process flow

Platform foundation and column grid production

First, make a round pedestal with White Marble stone carving effect, and accurately divide the three steps and railing positions. 28 gold columns and eaves columns need to be kept absolutely vertical, and the details of the column foundation and column head need to be hand polished. Using traditional mortise and tenon technology to connect columns and beams, forming a stable circular frame system.

Triple eave production

This is the difficulty of model making. Make eaves layer by layer from bottom to top, and first use wooden strips to make curved rafters for each roof layer, and then lay roof panels. The tile laying starts from the lower eaves, and each tile needs to be accurately pasted according to the actual building angle to ensure that the three-layer eaves form a beautiful decreasing curve. The upturned corners of the eaves need to be shaped separately, using steam to bend the wooden strips to achieve a natural upward curve.

Top and decorative details

The gilded treasure top needs to be made in pieces, with the top sphere rotated into a perfect circle using a lathe, and the lower lotus petal base finely carved. The partition of doors and windows is carved with a rhomboid lattice pattern with thin wood chips, and the arch of wooden architecture floor is assembled and installed with prefabricated small wood blocks to reproduce the exquisite and complex structure.

4、 Post processing and artistic coloring

Grassroots treatment

After all components are assembled, fill the joints with a mixture of wood powder and glue. After drying, use sandpaper to polish the surface of the wood from coarse to fine multiple times to achieve a smooth and silky effect. Spray a light gray primer as a whole to lay the foundation for subsequent coloring.

Layered coloring process

Roof painting: The entire roof is sprayed with Prussian blue base color, and jade green is applied at the tile and drip points to reproduce the brilliant color of glazed tiles. The ridge beast pieces are delicately outlined with gold paint.

Woodwork painting: The column and lintel parts are first coated with reddish brown primer, and then painted with fine brush and seal painting patterns, with green and green gold accents, to recreate the splendor of royal architecture.

Old foundation: the White Marble foundation is made of gray white, and the light gray stain lotion is used to emphasize the stone seam texture, creating a natural weathering effect.

Overall effect integration

Use diluted brown pigment for global aging treatment to make the color transition natural. Finally, spray matte protective paint to achieve a uniform texture. Install the completed building model onto the green velvet booth, equip it with a lighting system, illuminate it from the inside, simulate the changes in light and shadow at different times, and make the model a living artwork.