Semiconductor equipment model manufacturer

Case study of semiconductor equipment display model production

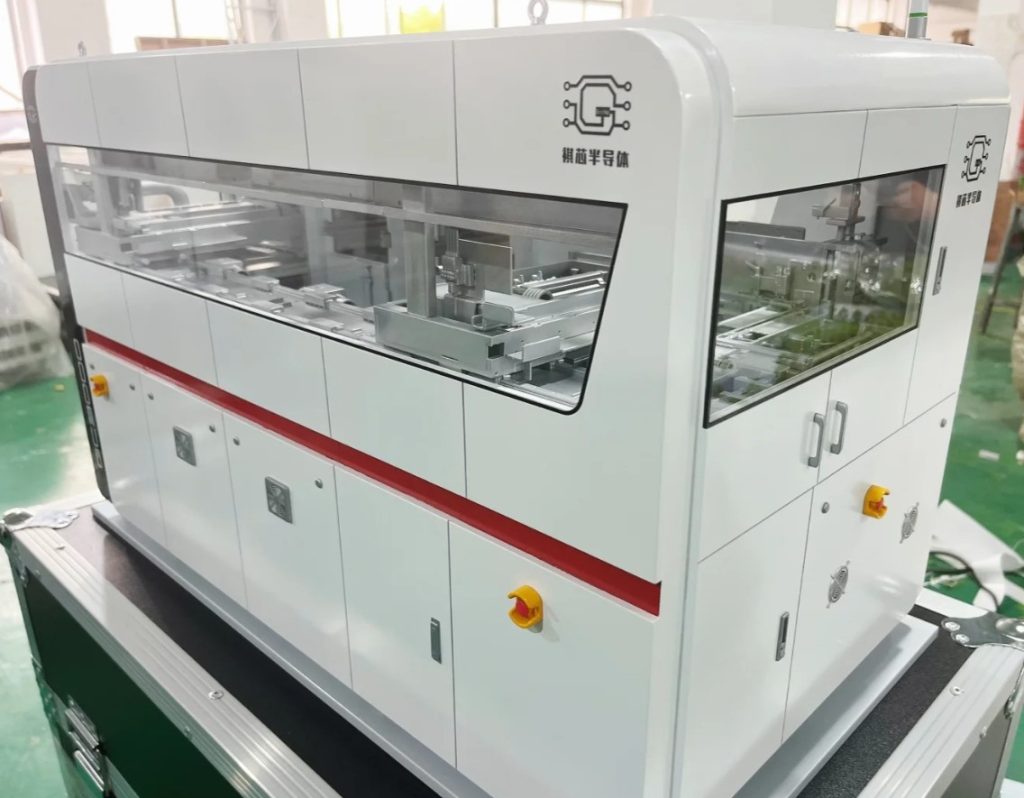

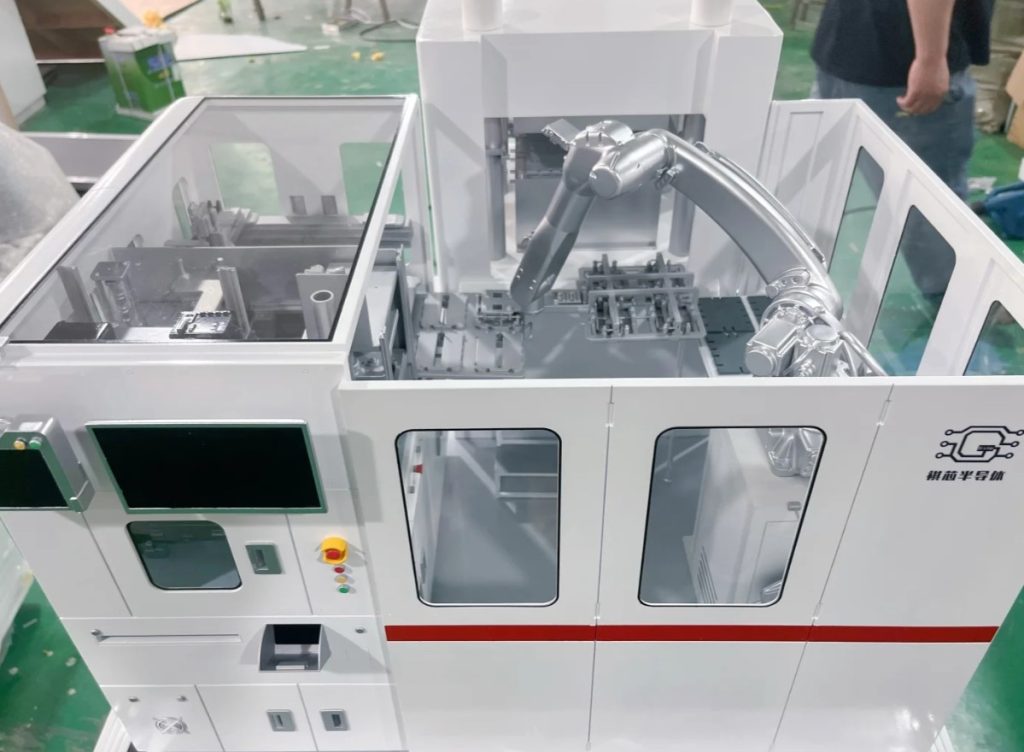

This production is a set of industrial semiconductor equipment models for exhibition display, with a scale of 1:10, including two typical equipment units shown in the figure. The production goal is to reproduce the professional industrial beauty of the equipment through fine manual craftsmanship, focusing on the white box structure, observation window details, and internal structural implications, with an overall restoration degree of 90%.

1、 Material selection and basic preparation

The main body of the model uses 5mm thick ABS engineering plastic board as the core material. ABS board is easy to cut and polish, and has good stability, which can perfectly present the square and flat appearance characteristics of industrial equipment. The observation window is made of 2mm transparent acrylic sheet to ensure transparency and strength. The bottom roller is modified with finished nylon wheels, and the internal structure is composed of copper thin tubes and gray ABS board.

2、 Main structure and detail production

The production adopts a layered construction method. Firstly, use ABS board to build the equipment foundation box, and all joints are designed with a bayonet style and bonded with model glue to ensure straight edges and stable structure. After the box is completed, the precision carving operation of the observation window opening is carried out, and the cut acrylic board is embedded and installed from the inside.

The internal structure is represented through simplification: gray ABS boards of different thicknesses are stacked and glued together to form a three-dimensional frame, and copper pipes are used to simulate cable layout. These structures are hidden behind transparent windows, maintaining overall aesthetics and reflecting practicality. The red decorative strip is precisely pasted with ABS fine strips after painting, and the edge treatment is clear and distinct.

3、 Professional painting and texture treatment

The painting process is divided into three stages. Firstly, spray a white primer as a whole, inspect and repair all surface defects. Then proceed with the main color spraying, using specialized industrial white matte paint, and achieve a uniform and thick coating effect through multi-layer thin coating.

Detail processing is a key step: use a hook pen to wash the panel joints with dark gray stains to enhance the three-dimensional sense of the structure; The internal components are treated with metal silver and dark gray color separation, forming a layered contrast through the observation window; The red decorative strip is finely sprayed three times to ensure a full and uniform color. Finally, the overall matte protective paint is sprayed to give the model a professional industrial equipment texture.